The sequencing batch reactor (SBR) is a fill-and-draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove undesirable components, and then discharged. Equalization, aeration, and clarification can all be achieved using a single batch reactor. To optimize the performance of the system, two or more batch reactors are used in a predetermined sequence of operations. SBR systems have been successfully used to treat both municipal and industrial wastewater. They are uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions.

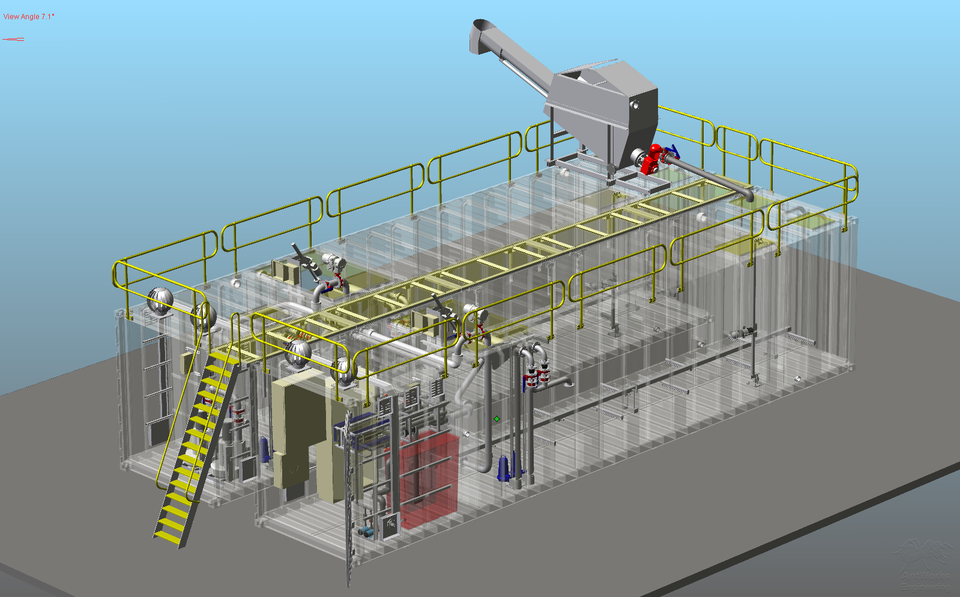

SBR systems consist of several treatment phases that make up a complete treatment cycle. Most systems operate from between 3 and 6 cycles per day. Our specialized primary treatment process allows cost-effective, redundant, single-tank, true SBR systems with no influent or turbulence during settling and discharge. WATEQ SBR’s provide excellent treatment quality and can be utilized for most any application above 10,000 gpd. WATEQ SBR design is capable of providing total nitrogen reduction (denitrification) and phosphorus reduction.

Advantages:

- The SBR is simple, cost effective, and can provide very effective treatment for the removal of BOD, TSS, ammonia, and nutrients such as nitrogen and phosphorus.

- SBR systems are uniquely suited for wastewater treatment applications characterized by low or intermittent flow conditions and can easily be adapted for variable pollutant concentrations.

- The SBR process handles variable flows and loading conditions better than conventional activated sludge plants since the number of cycles are automatically adjusted

- Equalization, primary clarification (in most cases), biological treatment, and secondary clarification can be achieved in a single reactor vessel.

- Operating flexibility and control.

- Minimal footprint.

- Potential capital cost savings by eliminating clarifiers and other equipment.

SBR Industries:

- Municipal sewage plants

- Automotive Industry

- Metal plating and finishing

- Chemical industries

- Pulp & paper

- Food & beverage

- Coke & steel plants

- Aquaculture & Koi ponds